Manufacturing Companies for Principles Of Slip Rings - Servo-system Slip Rings – AOOD Detail:

Servo System Slip Rings

Servo drive systems are an important part of modern motion control and widely used in automatic equipment such as industrial robots and rotary tables, their power, signals and data need to be transmitted from the fixed platform to the rotary platform through a slip ring. But due to the interference of encoder signals, common electrical slip rings are easily to cause errors and shutdown the whole system.

AOOD servo system slip rings utilize fiber brush technology and innovative multiple independent modular design for stable transmission, long lifetime and maintenance-free operation. They provide pneumatic channel, power, high speed data, I/O interface, encoder signal, control and other signals connections for the system, have been tested and proven compatible with SIEMENS, Schneider, YASKAWA, Panasonic, Mitsubishi, DELTA, OMRON, Keba , Fagor etc. motor drives.

Features

■ Suitable for SIEMENS, Schneider, YASKAWA, Panasonic, Mitsubishi etc. servo drive systems

■ Compatible with various communication protocols

■ Provide power, signal and pneumatic channels together

■ 8mm, 10mm, 12mm air channel size optional

■ Higher sealing protect optional

■ Stainless steel housing available

Advantages

■ Strong anti-interference capability

■ Flexible combination of power, data and air/fluid lines

■ Easy to mount

■ Long lifetime and maintenance-free

Typical Applications

■ Packaging systems

■ Industrial robots

■ Rotary tables

■ Lithium battery machinery

■ Laser processing equipment

| Model | Channels | Current (amps) | Voltage (VAC) | Size | Bore | Speed | |||

| Electrical | Air | 2 | 5 | 10 | DIA × L (mm) | DIA (mm) | RPM | ||

| ADSR-F15-24&RC2 | 24 | 1 | × | 240 | 32.8 × 96.7 | 300 | |||

| ADSR-T25F-3P6S1E&8mm | 14 | 1 | × | × | 240 | 78 × 88 | 300 | ||

| ADSR-T25F-6&12mm | 6 | 1 | × | × | 240 | 78 × 77.8 | 300 | ||

| ADSR-T25S-36&10mm | 36 | 1 | × | 240 | 78 × 169.6 | 300 | |||

| ADSR-T25S-90&10mm | 90 | 1 | × | 240 | 78 × 315.6 | 300 | |||

| ADSR-TS50-42 | 42 | 1 | × | × | 380 | 127.2 × 290 | 10 | ||

| Remark: Pneumatic channel size is optional. | |||||||||

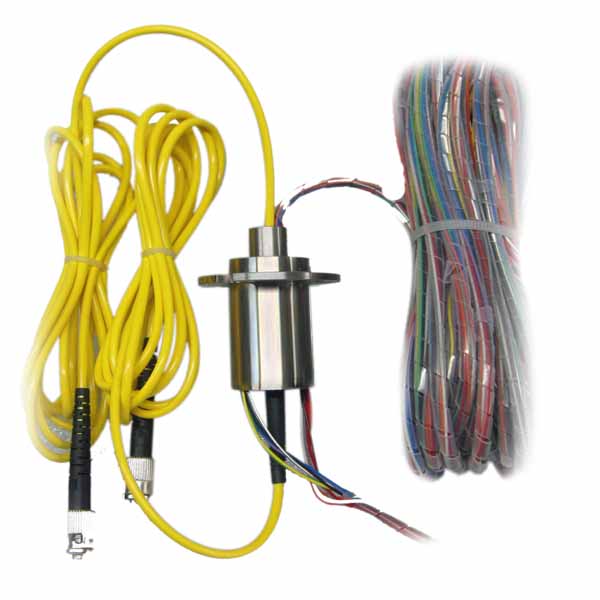

Product detail pictures:

Related Product Guide:

Cooperation

We persist with the principle of quality 1st, assistance initially, continual improvement and innovation to meet the customers for your management and zero defect, zero complaints as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Manufacturing Companies for Principles Of Slip Rings - Servo-system Slip Rings – AOOD, The product will supply to all over the world, such as: Dubai, Lahore, Estonia, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!