For Power

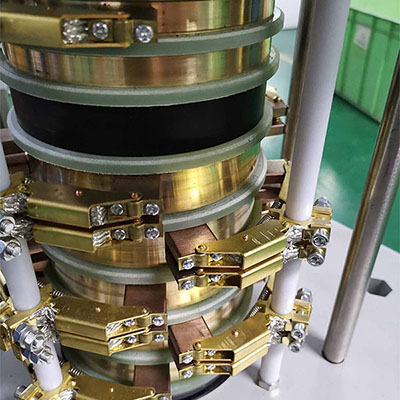

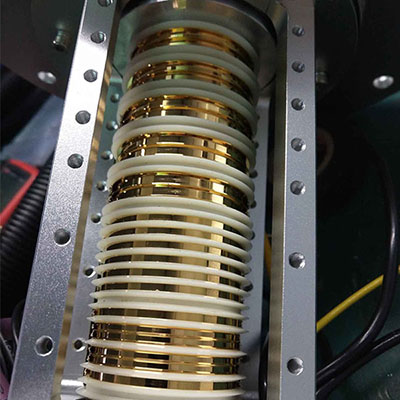

To realize the unrestricted transfer of high current/ power in a slip ring system, we have traditional carbon brush contact technology, advanced multiple-point fiber brush contact technology and mercury contact technology available. The single channel rated current up to 500A and rated voltage up to 10,000V. Moreover, we have rolling-ring contact technology to achieve smaller dimensions, higher current loading and longer lifetime with maintenance free requirements of electrical slip rings.

Features:

■Rated current up to 500A per channel, rated voltage up to 10,000V

■Carbon brush, mercury, fiber brush and rolling-ring contact technology optional

■Maximum operating speed up to 10,000rpm

■Sealing up to IP68

■Maximum channels up to 500 channels

■Can combine with signal slip ring, FORJ and gas/liquid rotary joint

For Communication

A multi-channel electrical slip ring is often required to transfer different types of communication protocols in industrial automation and military applications, such as EtherCAT, CC-Link, CANopen, ControlNet, DeviceNet, Canbus, Interbus, Profibus, RS232, RS485, Fast Ethernet and Fast USB. For different communication protocols, we adopt separate module design to ensure each type of protocol’s stable transmission and not be disturbed by other protocols and power of the same slip ring. The high speed digital signal module up to 500Mbit/s speed, all our standard and custom designed slip rings can be integrated with these communication modules to meet the needs of different applications.

Features:

■The digital signal transfer speed up to 500Mbit/s

■Multiple points fiber brush contact technology

■Robust configuration ensure the stability and reliability of signal transmission

■Integrate with FORJ, RF rotary joint and hydraulic or pneumatic rotary joint available

For Signal

We are experienced in all kinds of signal treatment, especially for some special signals, such as encoder signal, thermocouple signal, 3D acceleration signal, temperature sensor signal, PT100 signal and strain signal. We use separate module design to ensure minimal signal loss and interference even the slip ring is under high speed operating or in EMI environment.

■Signal transfer frequency up to 500MHz

■Capable of transferring absolute and incremental encoder signals

■Module design ensure minimal signal loss and interference

■Unique design allows signal’s stable transmission under high speed operating or EMI environment

■Integrate with FORJ, RF rotary joint and hydraulic or pneumatic rotary joint available

For Special Applications

In addition to common industrial slip rings, we also provide customized high performance slip rings for special environment, for instance high speed high temperature downhole slip rings for oilfield, dust-proof and explosion-proof slip rings for mining machinery and large dimension slip rings for industrial sewage treatment. Technically, our slip rings’ maximum operating speed up to 20,000rpm, central through hole diameter size up to 20,00mm, up to 500 ways, digital signal transfer speed up to 10G bit/s, temperature up to 500 C and sealing up to IP68 @ 4Mpa.